As a worldwide innovator in high-performance adhesives, sealants, and precision dispensing equipment, Hernon Manufacturing, Inc. creates custom adhesives for companies across the globe. We offer a complete array of solutions for our clients—including customized formulas, dispensing equipment, and UV curing equipment—to support an efficient, cost-effective design and production process.

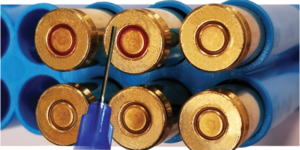

With over 40 years of engineering excellence behind us, our research and development team has developed over 5,000 formulas. These formulas are used in a wide range of different industries including Ammunition Manufacturing, Energy and Power Generation, Medical, Electronics, Electrical, LED, Automotive, Appliances, Sporting Goods, Ammunition, Communications, Aerospace, Aviation, High Tech Audio, Defense, Fire Suppression, Transportation, Marine Manufacturing and more.

HERNON’s world headquarters is located in Sanford (Orlando), Florida, USA – a high-tech community developing aerospace, power generation, electronic, and optical solutions for the world. The Central Florida region is also the birthplace of America’s presence in space through Cape Canaveral. This location allows our Research and Development team an opportunity to work side-by-side with other companies developing cutting-edge technology.

Hernon Manufacturing, Inc.® has been recognized as a top company in Orlando and recently received the 2015 Presidential “E” award for exports. HERNON® was also recognized in 2015 as a community and business leader by the Seminole County and Sanford Chambers of Commerce. In addition, HERNON’s CEO, Harry Arnon, was named 2015 CEO of the year by the Orlando Business Journal for his acumen displayed by guiding Hernon Manufacturing to record growth and expansion despite a subdued economy. Hernon Manufacturing has also been recently recognized at the 2016 Bright House Regional Business Awards as a leader of New Product Development for small caliber ammunition sealing.

Learn more and see additional products at Hernon.com